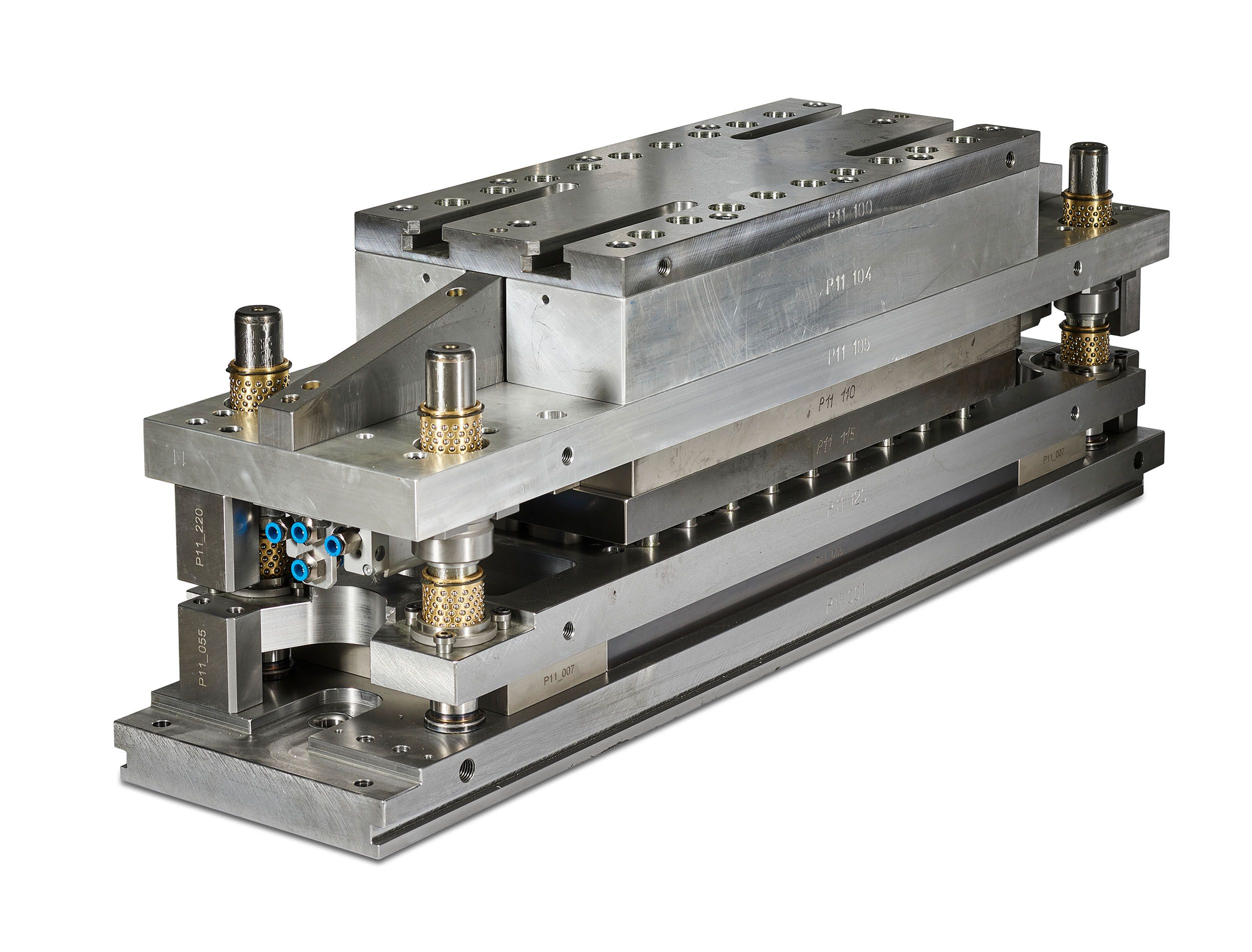

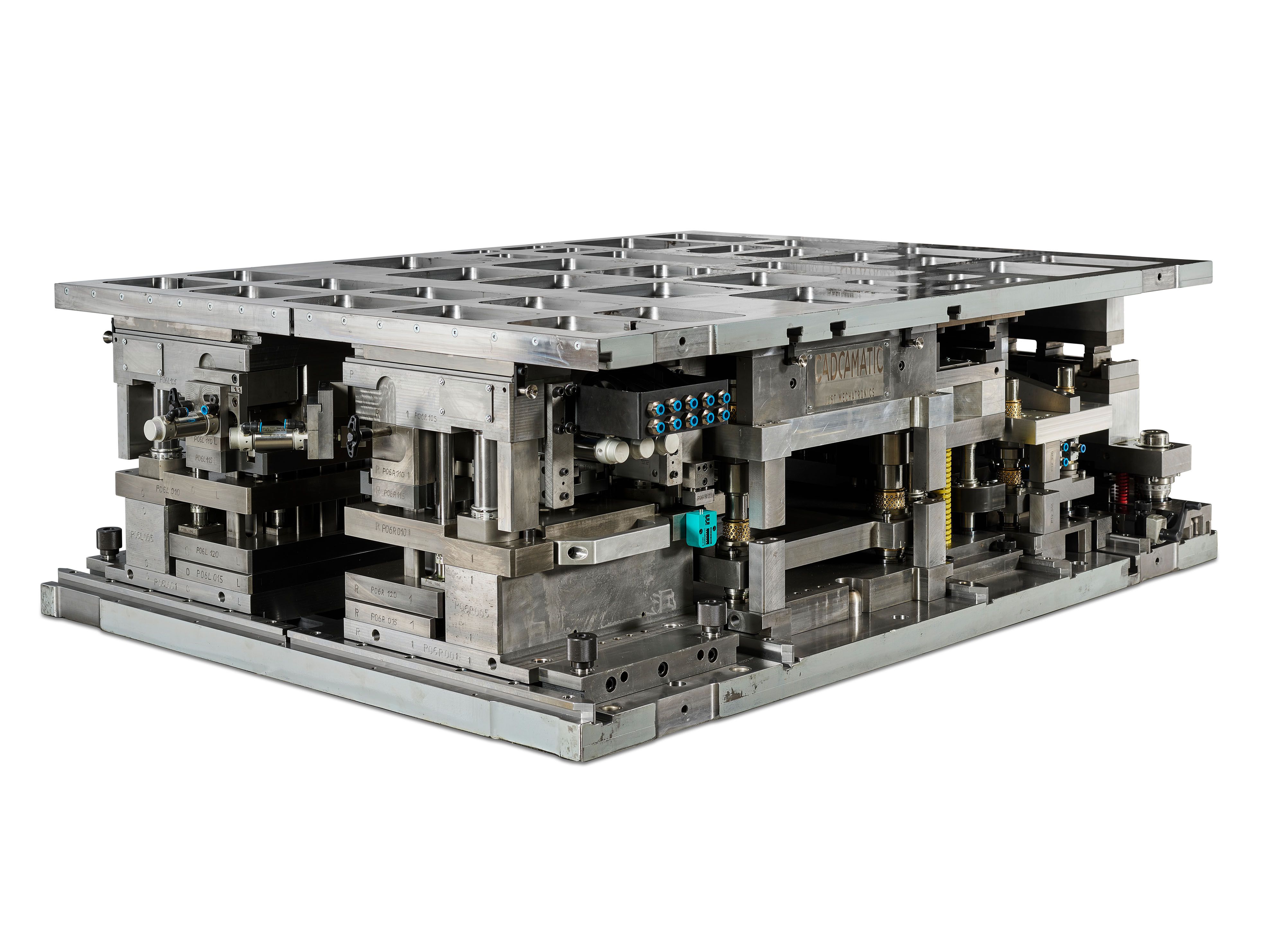

CASE: REALISATION OF A UNIVERSAL MOULD

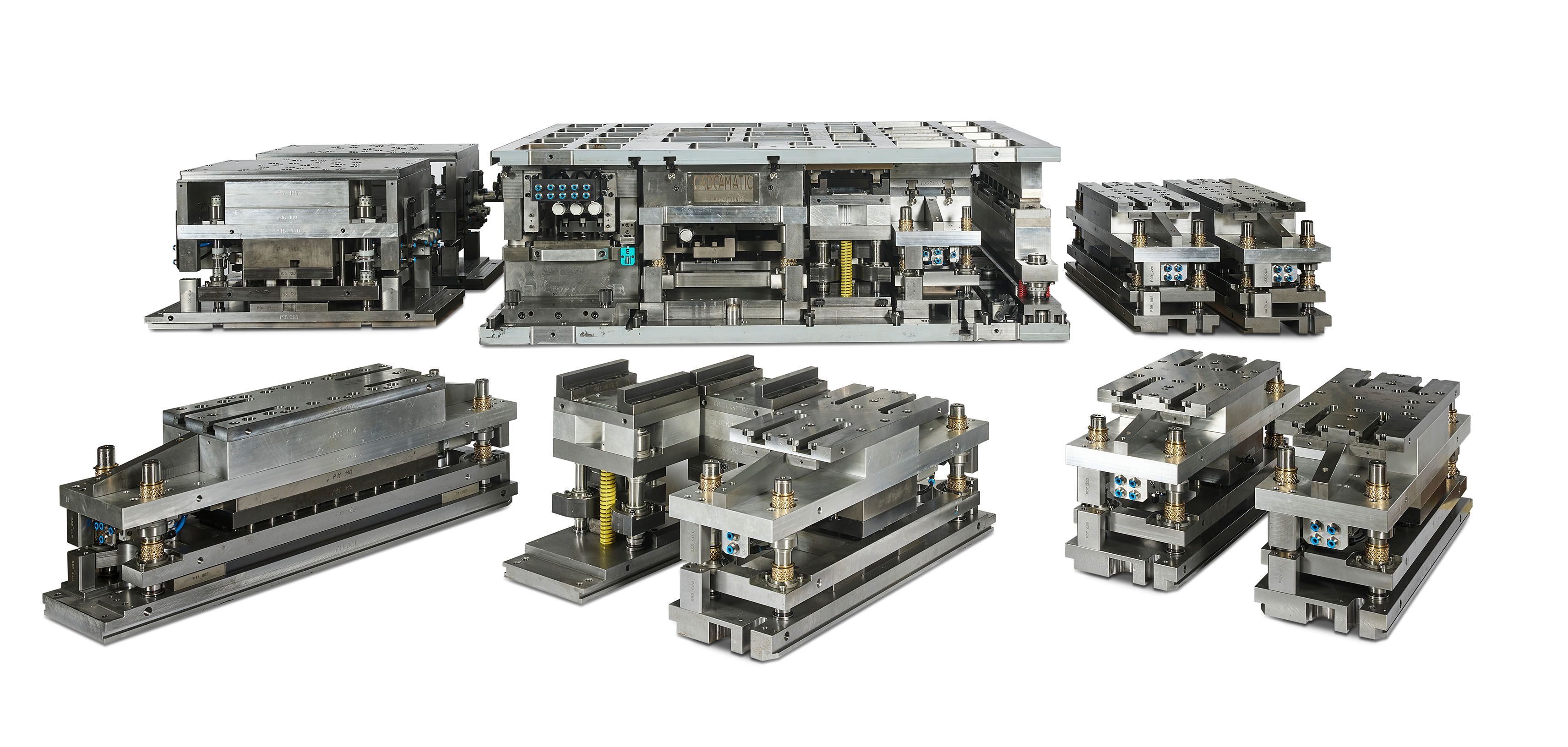

For a customer in the construction industry, we were asked to design and realise a universal mould for the production of a very large range of products starting from different coil widths and thicknesses in steel and stainless steel.

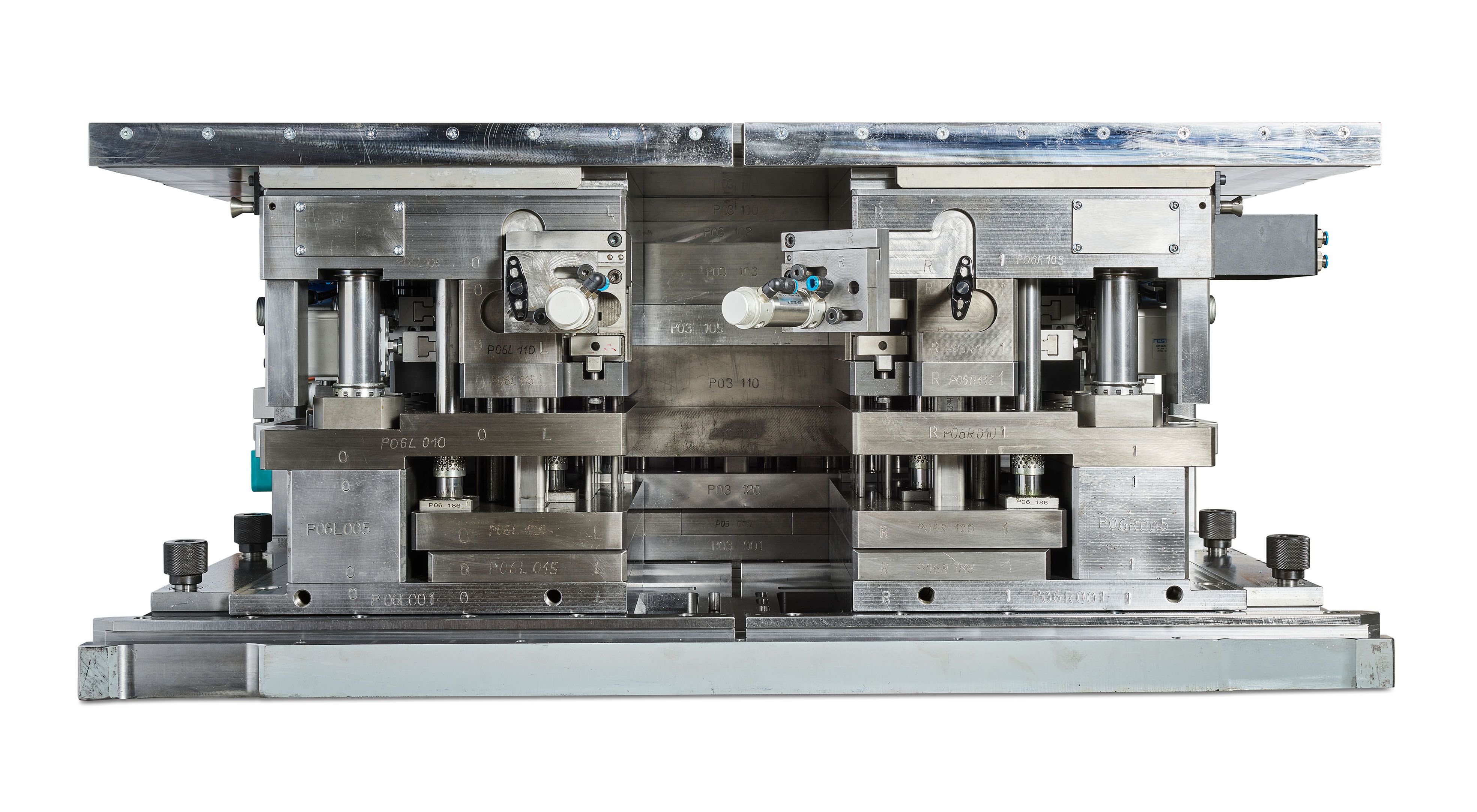

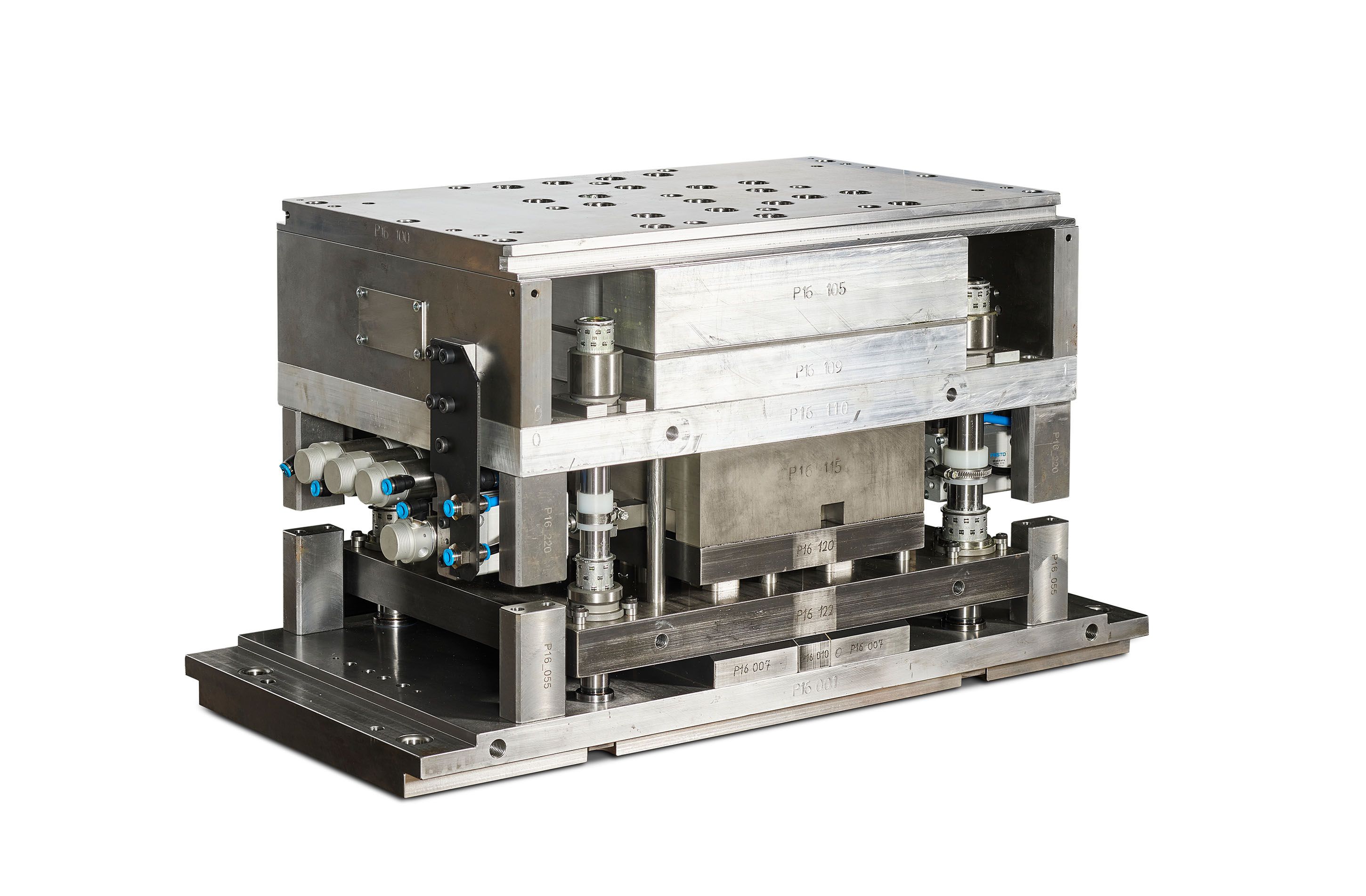

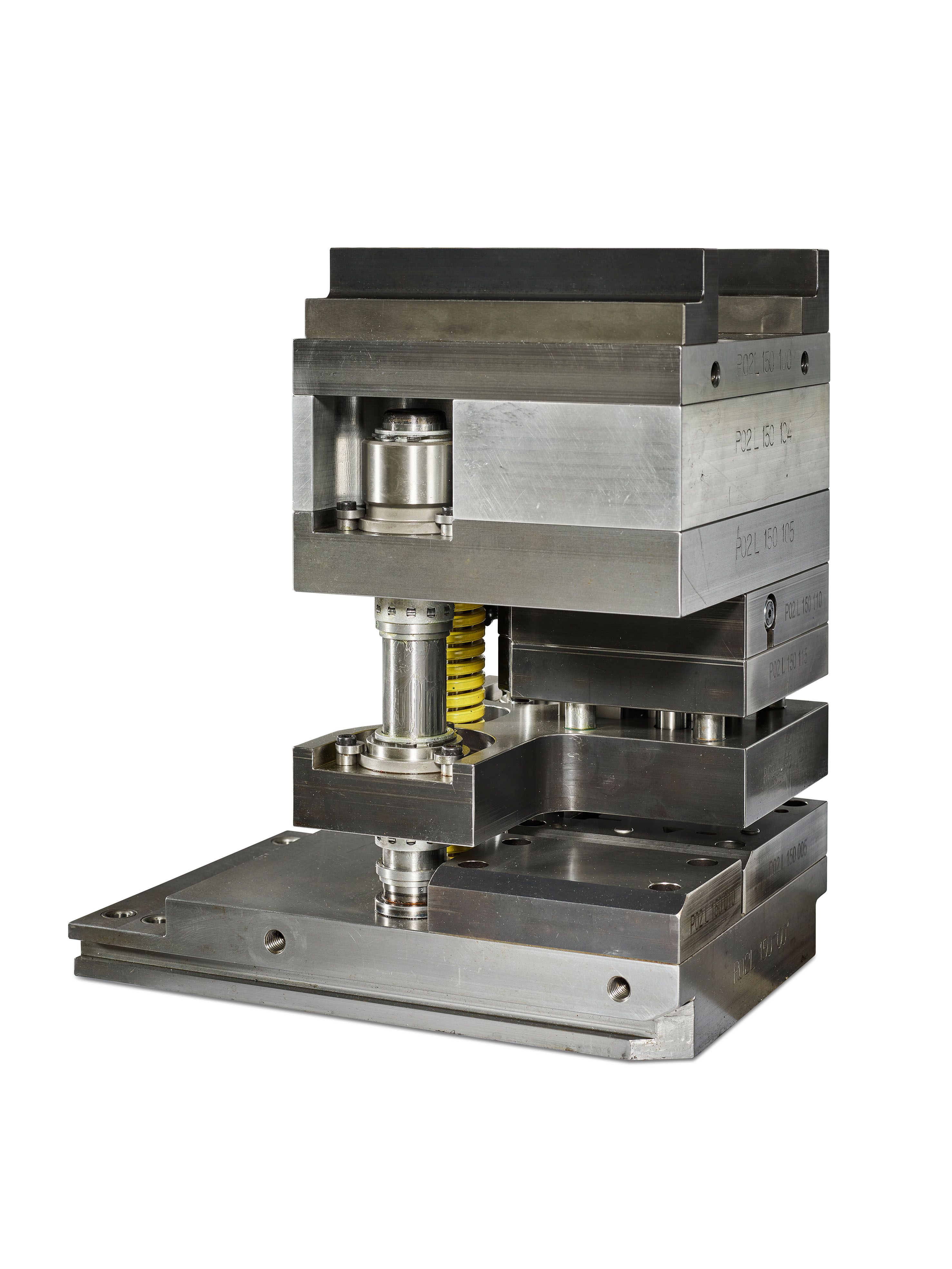

We ensured a very short change-over time from one product to another by using special changeable sliding techniques and pneumatically switchable punches. The different compact sub-dies can be shifted depending on the coil width or quickly exchanged so that the main die can always remain in the press.

All sub-dies are equipped with ball-bearing guides with which we can achieve a production speed of 180 strokes/min.

The result is impressive.

Interested in a tailor-made solution for your company?

Contacteer Kristof Pardaens voor meer info k.pardaens@cadcamatic.be

nl_BE